PRODUCTS + EXPERTISE = SOLUTIONS

Solenoid Valves – Pinch Valves

Pneumatic Control Products

Ball Valves – Check Valves

Quick Disconnect Couplers

GETTING WHAT YOU WANT STARTS HERE

Our products and expertise enable us to provide application specific solutions for the Medical, Life Science, Pharmaceutical, Food & Beverage, Water, Chemical and General Industrial sectors.

Product Categories

AKO

AKO manufacture air operated and manually operated pinch valves. With there unique design pinch valves are the ideal control valve solution for abrasive, corrosive and fibrous products, such as granulates, powders and liquids containing solids.

AuK Muller GmbH

AuK Müller manufacture of solenoid valves, control equipment and specialty valves. With an emphasis on OEM applications Muller have extensive experience in providing valves for a wide range of applications for the Sanitary, Vending, Medical, Agricultural/Food, Industrial and Environmental Technology sectors.

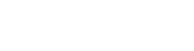

Clippard

Clippard manufacture miniature pneumatic valves, cylinders and fittings. The complete line of over 5,000 standard products includes Pneumatic Cylinders, Electronic Valves & Proportional Devices, Directional Control Valves & Accessories, Modular Valves, Pneumatic Circuit Assemblies, Filters / Regulators / Lubricators, Fittings, Hose & Tubing, Custom Solutions, and Value-Added Assemblies.

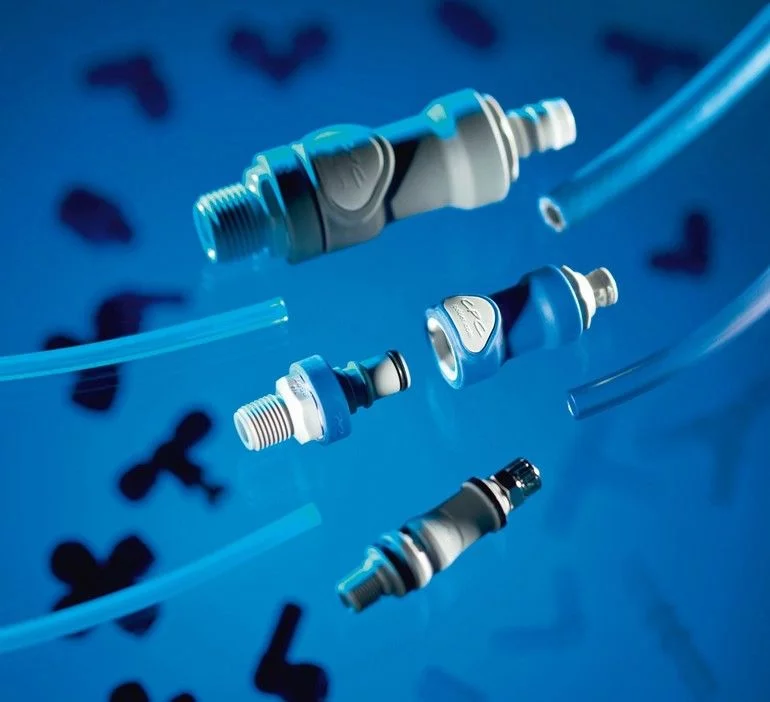

CPC

CPC manufacture quick disconnect couplings, fittings and connectors for life sciences, specialty industrial and chemical handling markets. Used in a broad range of applications, CPC’s innovative coupling and connection technologies allow flexible tubing to be quickly and safely connected and disconnected.

GSR Ventiltechnik

GSR manufacture solenoid valves, pressure-controlled valves, motorized valves and accessories. With a comprehensive range of valves including low and high pressure & low and high temperature options and the core ability to offer customised variations on standard valves GSR are uniquely placed to provide valves according to your specifications.